LS1 to LS6 PCV conversion

E-mail jmX with corrections

Click here for a printable version

| Tools Needed: |

- 8mm, 10mm, 22mm (or 7/8") sockets - Flathead screwdriver - Pliers - 3/8" fuel line disconnect tool - Dremel with 5-10 small fiberglass reinforced cutoff wheels - lots of shop rags - Masking tape - Safety goggles or glasses |

| Parts you will need: |

Parts: - 1x 2001+ LS6 Engine Valley Cover (1x GMPN 12568002) - 1x Valve cover plug (1x GMPN 12568011) - 10 inches of 5/16 ID Rubber fuel line from autoparts store OR 1x GMPN 12568010 (expensive!) - 1 5/16" vacuum cap, if your LS6 cover doesn't come with a red one pre-installed Bolts/gaskets: - None needed (valley cover comes with new gasket already) Supplies: - Shop rags, roll of paper towels - 2" wide duct tape - Vacuum cleaner |

| Intro: |

|

Many LS1 owners are faced with a few issues. There's the oil pumps that randomly die, the rod bolts that randomly break, roller rockers that randomly lose their bearings, and the oil consumption issue that seems to haunt some and not others. The oil consumption issue seems to be one of the most common issues on all LS1's out there, and this is due to the way the stock PCV (Positive Crankcase Ventilation) system is setup. A PCV system is designed to force any positive crankcase pressure into the intake manifold, rather than continue allowing the engine to build up pressure inside. The LS1 system just happens to force oil along with the air as well, so GM seemed to take a stab at fixing the issue with the LS6 system. The LS6 setup pulls the pressure not from the valve cover, but from the VALLEY cover. This is the cover that resides under the intake manifold, and sits between the 2 cylinder heads. In this writeup, I'll show you what all is needed to convert your LS1 over to the new LS6 style PCV setup. We will do this all for about $65 in parts (or $120+ if you buy the LS6 pcv hose rather than constructing one yourself as I show below). NOTE: You must have the 2001+ style coolant vent tube as well for the LS6 valley cover to fit! All 2001+ LS1's will have this, and any LS1's that have upgraded to the "LS6 manifold" and pipes will also have the new coolant vent tube. |

Lets begin:

|

Note: f-body specific instructions will be blue, and C5 specific instructions will be green. Some pictures from this install will be from an F-body, some from a C5, however, none of the car differences will matter in the photographs. |

|

Disconnect each wire plug going to the each of the 8 injectors. To do this, push upwards on the shiny metal clip on the bottom of the plug, then pull of plug outwards off the injector. |

|

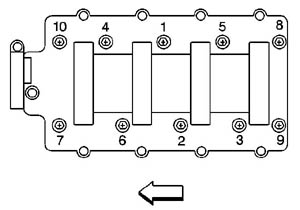

Using a 22mm (or 7/8" if you don't have a 22mm) socket and an extension, unbolt the knock sensors from the engine block and remove them. They are identical so it doesn't matter which is which. |